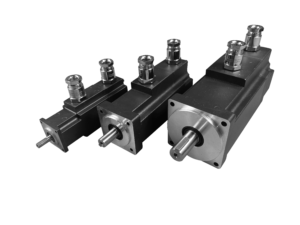

The Research and Production of Explosion-Proof Servo Motors

Explosion-proof servo motors play a crucial role in industries where hazardous environments are a constant concern. These motors are specifically designed to operate safely in areas where flammable gases, vapors, or dust particles are present. In this blog post, we will delve into the research and production processes behind these specialized motors.

Extensive research and development are undertaken to ensure the highest level of safety and reliability in explosion-proof servo motors. Engineers collaborate closely with industry experts and regulatory bodies to understand the specific requirements and standards for different hazardous environments. This involves studying the characteristics of the hazardous substances, identifying potential ignition sources, and developing appropriate protection measures.

One of the key aspects of producing explosion-proof servo motors is the selection of suitable materials and construction techniques. These motors are built to withstand extreme conditions, such as high temperatures, corrosive substances, and mechanical stress. Robust enclosures, made from materials such as stainless steel or cast aluminum, provide a barrier against potential explosions. Additionally, seals and gaskets are used to prevent the ingress of hazardous substances into the motor.

Another critical element in the production process is the implementation of safety features. Explosion-proof servo motors are equipped with advanced technologies like temperature sensors, pressure relief mechanisms, and flameproof enclosures. These features ensure that any potential ignition sources are effectively contained and isolated.

Furthermore, rigorous testing and certification procedures are conducted to validate the performance and safety of explosion-proof servo motors. These tests simulate various hazardous conditions, including exposure to flammable gases and dust particles, to ensure that the motors meet the required standards. Certifications from recognized organizations provide assurance to end-users that the motors have undergone stringent quality control measures.

In conclusion, the research and production of explosion-proof servo motors involve a meticulous process that prioritizes safety and reliability. Through continuous innovation and adherence to industry standards, these motors enable industries to operate efficiently in hazardous environments while minimizing the risk of explosions.

No Comments