The necessity of explosion-proof servo motors in industrial automation

In industrial automation, explosion-proof servo motors are of great necessity, mainly reflected in the following aspects: Safety and reliability requirements: In certain industrial environments, such as chemical plants, oil drilling…

Application scenarios of explosion proof servo motors in coal mines

Coal mine explosion proof servo motors are mainly used in flammable and explosive environments such as coal mines to provide precise motion control and driving force, while ensuring the safe…

Common classifications for explosion-proof applications

Explosion proof situations are usually classified based on the potential explosive nature and degree of danger. The following are some common classifications of explosion-proof situations: Regional classification: Zone classification: Areas…

Classification of explosion-proof occasions

Explosion proof equipment is usually used in situations where it is necessary to prevent sparks, static electricity, or other potential explosions. These devices can be used in the following situations:…

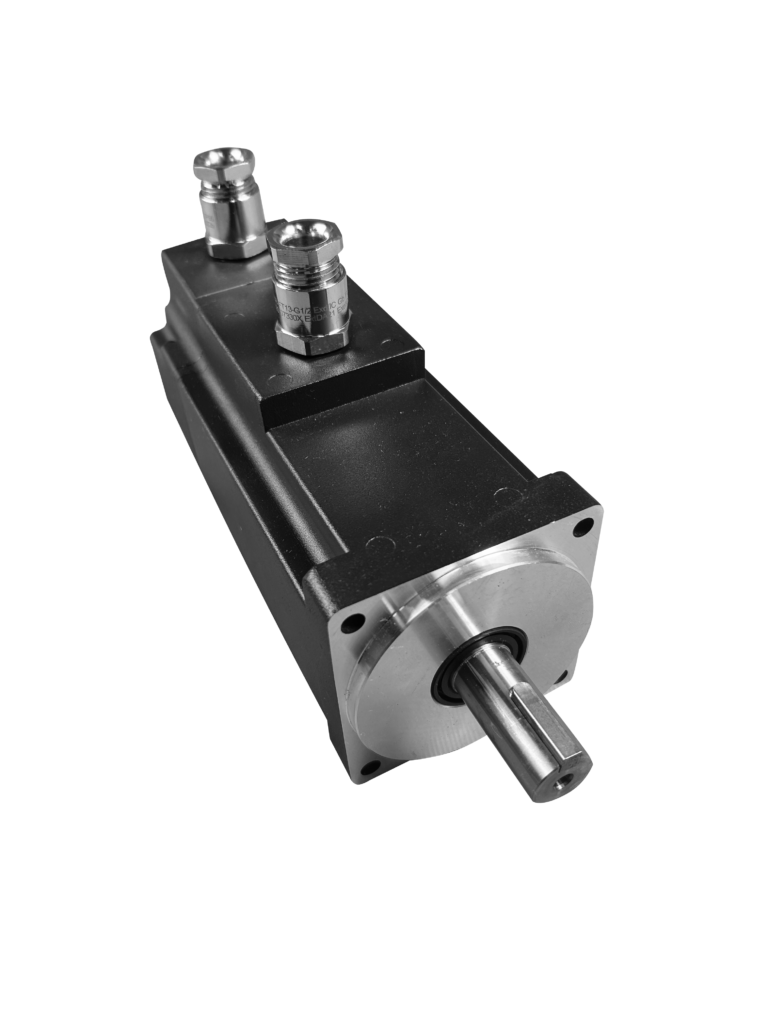

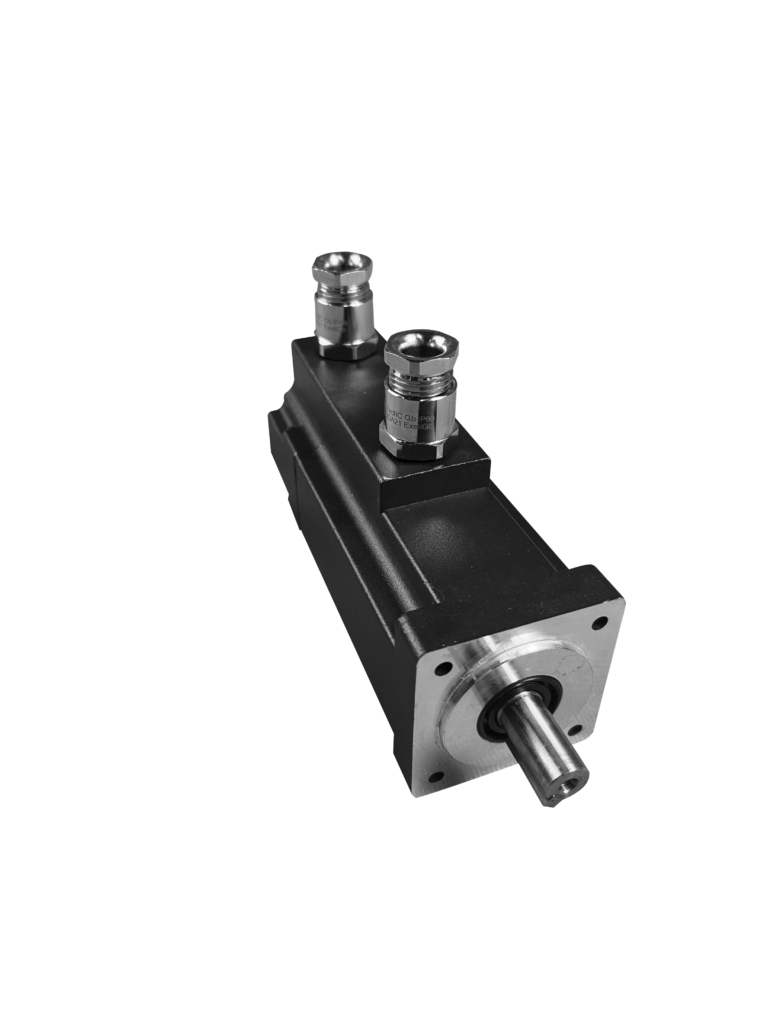

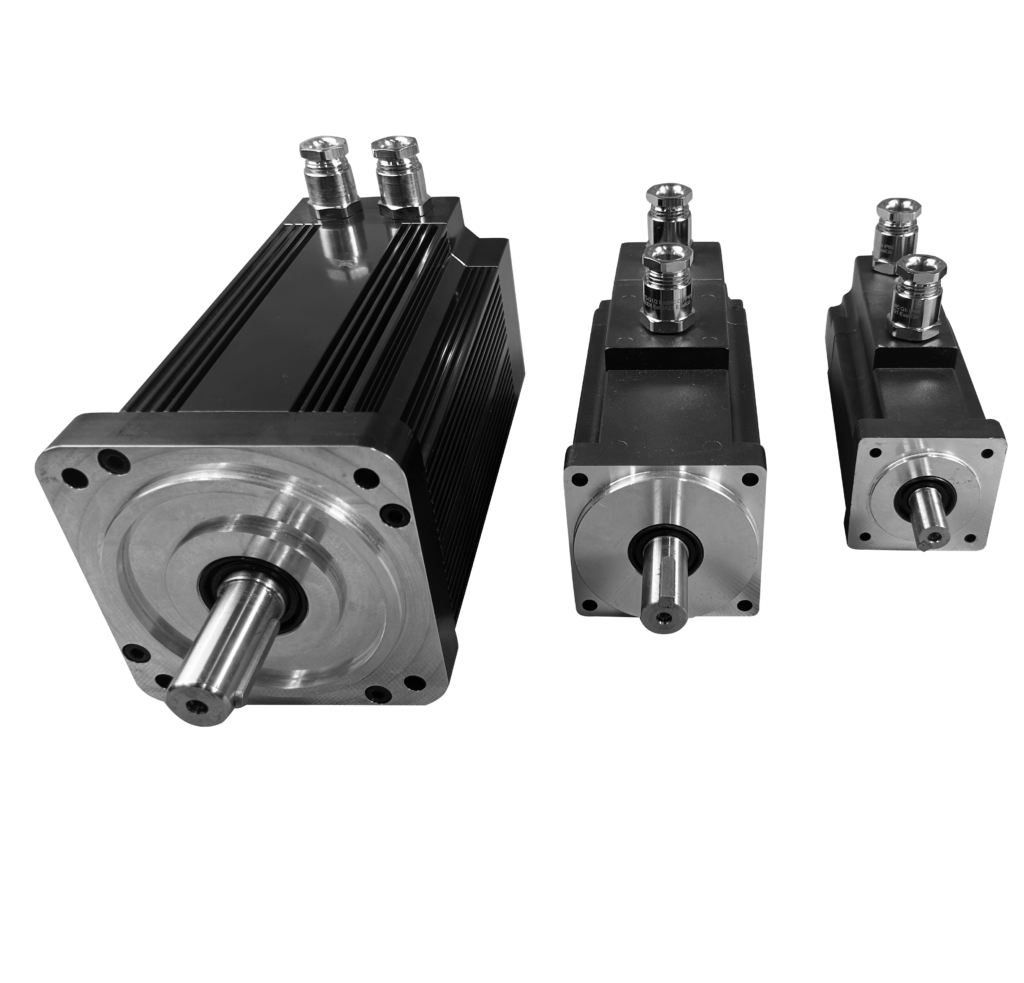

The particularity of explosion proof servo motors

Explosion proof servo motors have some special performance, making them safer and more reliable in specific environments. These performances mainly include: Explosion proof performance: Explosion proof servo motors are designed…

The Application of Explosion Proof Servo Motors

In industrial environments where safety is paramount, the use of explosion proof servo motors plays a critical role. These specialized motors are designed to operate in hazardous areas where the…

Types of explosion-proof equipment

Explosion proof equipment can usually be classified into several types based on its purpose and application environment: Explosion proof electrical equipment: Used for electrical equipment in hazardous environments, such as…

Common explosion proof level standards

防爆等级是用于确定快速设备、工具或区域对爆炸性环境的耐受能力的标准。一般来说,防爆等级描述了设备在气体、蒸汽、死亡等潜在危险环境中的安全性能。常见的防爆等级标准包括: ATEX等级:适用,分为两个指令,一个是针对气体环境的ATEX 114(94/9/EC),另一个是针对工业环境的ATEX 153(99/92/EC)。 IECEx等级:由国际电工委员会(IEC)管理,是一项国际标准。IEC 60079 标准涵盖气体和蒸汽环境(IEC 60079-0 至 IEC 60079-15)以及氢气环境(IEC 60079-31)。 UL等级:美国常用的认证标准,适用于爆炸性气体和蒸汽环境。 在这些标准中,防爆等级通常由数字和字母组成,数字代表设备的防爆能力等级,字母代表适用的爆炸性环境类型。例如,常见的防爆等级包括: Ex d:防爆型,适用于有可燃气体或蒸气的区域。 Ex e:增安型,适用于电气设备中限制电火花或温度的区域。 Ex i:防爆型,适用于防止电气设备在可燃气体环境中引起爆炸。 Ex p:压力密封,适用于控制有可燃气体或蒸气的环境中的压力。 不同行业和国家可能遵循特定的防爆等级标准,以确保设备在危险环境中的安全性能。

The reliability of explosion proof servo motors

"Discover Unrivaled Safety and Precision with Our Explosion-Proof Servo Motors! Engineered for excellence, our servo motors redefine reliability in hazardous environments. Ideal for industries requiring top-notch safety standards, these motors…

Working principle of explosion proof servo motor

防爆伺服电机的工作方式与普通伺服电机类似,但设计时考虑了在有爆炸风险的环境下使用的特殊要求。以下是防爆伺服电机的基本工作原理。 1、电机部分:防爆伺服电机的核心是电机,通常为交流伺服电机。这类电机可以通过控制电流的大小和方向来控制电机的运行和位置。 2、传感器:防爆伺服电机配有各种传感器,如位置传感器、速度传感器、行程传感器等。这些传感器用于实时监控电机的状态并向控制系统提供反馈。 3、控制器:控制器是防爆伺服电机的智能核心,负责处理传感器提供的反馈信息,并根据预定的控制算法调整电机的运行状态。这通常包括PID(比例积分微量)控制器等。 4.防爆设计:防爆伺服电机在设计时考虑了特殊的防爆材料和技术。例如,电机的外壳可以采用防爆材料制成,以防止危险环境中发生爆炸。 5、电气防爆:防爆伺服电机的电气部分经过特殊设计,保证运行时不会引起爆炸。这可能包括防爆接线盒、防爆电缆以及电气对的特殊密封和防火措施。 6、温度控制:由于危险环境下可能出现高温,防爆伺服电机通常配备温度控制系统,以确保极端条件下的安全运行。 7、防爆等级和地区分类:防爆伺服电机通常根据其防爆等级和地区分类进行设计。这些标准确定了在不同危险环境中使用的设备需要满足的具体要求。